Statistical Process Control (SPC) is a method used to monitor different processes in manufacturing. The methods designed to monitor whether the process is in control or not, and what ability it has to produce units (can be both goods and services) that are within set tolerances.

In all types of processes there exists variation. In a manufacturing process, usually variables like temperature and humidity, or poorly calibrated measuring instruments that makes the variation. This variation is a source of poor quality, and therefore must be identified, monitored and, if possible, reduced. In the study of process there exists itself variations, which must be considered in the arrangement and interpretation of the study.

Variation can be of various types. Often mentioned discrete and random variation and engineers like to speak in terms of signal and noise. The purpose of SPC is to:

- Identify causes to variation and eliminate them

- Monitor the process as it is in statistical control SPC

- Continuously capture information from the process so that new causes of variation can be identified

For this purpose, an SPC Software is used.

PQSYSTEMS

PQ Systems helps people in manufacturing, healthcare, government, and service organizations with our software, including SPC Software, and services…

- SPC Charts

- SQCpack Six-Way Analysis

- Complete Customization

- Feedback Anytime

- Alerts

- StatBoard

- Security

- Audit Trail

- Filtering

- SPC Data Collection

- Reporting

- Scalability

PREDISYS

Statistical Process Control (SPC) Software for Manufacturing SPC and Quality Control.

- Effortlessly utilize data from manufacturing processes to help reduce scrap and improve product quality

- Get insight, understand complexity and reduce the cost of compliance

- Collect and manage product quality data from any production phase and from a virtually any data source

- Eliminate and streamline manufacturing practices

- Collaborate with their suppliers to proactively ensure that incoming components satisfy quality requirements

- Manage and standardize their quality processes to reduce the cost of quality

- Utilize manufacturing process intelligence across their supply chain to reduce NPI and time-to-market

- Transform their return/warranty data into actionable insight to help cut costs and increase customer satisfaction

- Save on operational IT costs

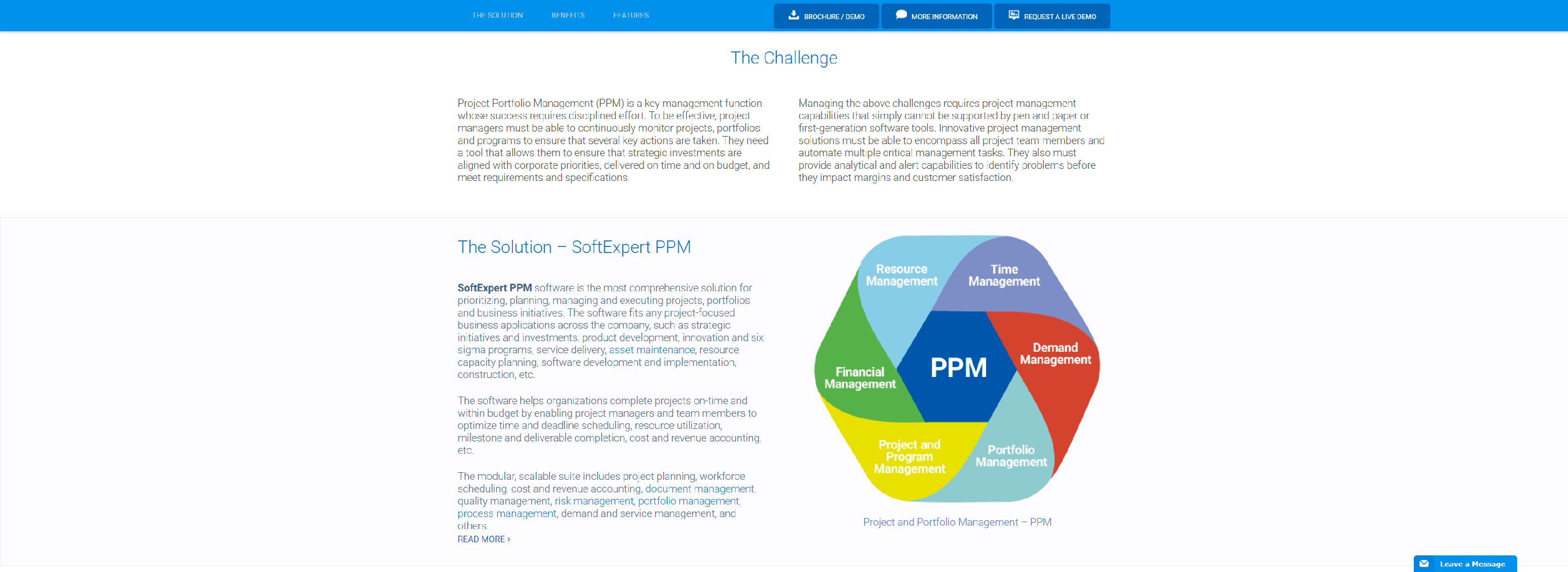

SOFTEXPERT

Solutions for management excellence with software for business process improvement, regulatory compliance and corporate governance.

- Monitors process quality

- Instantly signals problems or anomalies detected in processes during data collection

- Sends violation data to an event log or alerts operators to enter information, such as possible causes, annotations and corrective actions

- Provides information to justify changes in processes

- Supports process capability (Cp, Cpk) and process performance (Pp, Ppk) analyses compared to product tolerance

- Multiple SPC graphics can be simultaneously displayed and updated in real time, including charts (XR, XS, p, np, c, u), histograms, Box Plots, average, amplitude and standard deviations, traffic light charts and evaluation bands, among others

- It allows for data collection, in a simple manner, using screens similar to a spread sheet

- And More.

ICONICS

![]()

ICONICS provides an extensive set of SPC calculations, control charts, portal dashboard views, and standard quality reports to help pinpoint quality outliers and drive corrective actions based on process trends.

- Take Action and Improve Product Quality

- Easy Configuration of Multiple Charts, Grids, Tiles, and Graphic

- Extensive Statistical Calculation Library

- Quality Deviation Detection and Alarm Rule Customization

- Discover Hidden Costs

- Universal Connectivity

INFINITYQS

Statistical process control (SPC) software from InfinityQS seamlessly collects quality data across the supply chain, for extensive enterprise visibility.

- Improve Data Collection, Analysis, and Reporting

- Reduce Scrap, Waste, and Risk

- Optimize Manufacturing Operations

- Increase Savings and Yields

IQMS

IQMS offers a comprehensive manufacturing, MES and ERP software system to help manufacturers increase efficiency and drive more profitable revenue growth.

- Eliminate non-value added processes

- Eliminate unplanned downtime

- Prevent bottlenecks in the manufacturing process

- Operate with near 100% machine utilization

- Optimize scheduling and resource allocation regardless of the plant location

- Have complete unimpaired visibility and traceability of the entire manufacturing process from raw material, through customer delivery

- Comply with quality standards

HERTZLER

Hertzler software and services enable clients to connect, collect, and analyze data, building a data infrastructure for making data-driven decisions.

- Connectors to any automated data source to streamline automation and data connectivity

- User-configurable scripting to empower your team to manage your deployment

- Robust charting and analytics tools

- Data wizards that quickly and automatically make the root cause of variation visible

- Role-based dashboards that deliver the right information to the right people in real-time

LIGHTHOUSESYSTEMS

World-leading Manufacturing Execution System software for real-time manufacturing operations data at your fingertips; web-based, flexible and powerful.

- Configure your SPC Charts

- Real-time SPC analysis and alerting

- Charts for line operatives

- Further process variations analysis

- Calculate process capability

WINSPC

WinSPC delivers process improvement for manufacturing using Statistical Process Control – SPC Software to detect and prevent waste, scrap and rework.

- Supply Chain Quality

- Capture Data

- Monitoring and Alarming

- Analysis and Reporting

Statistical Process Control: What It Actually Does For You

You are encountering quality control problems with your production line, and need to monitor your factory’s processes. The Statistical Process Control can help you find out if changes have occurred within your company’s production in your absence. Many companies are already using various SPC methods, such as control and management charts for different purposes. SPC methods such as those mentioned above can reduce the chances of variation occurring within your production lines, and improve the overall manufacturing process. SPC can also help you meet customer satisfaction and certification standards.

Each process has one or more outputs. Each output, in turn, has its own attributes that can be measured. The idea that these said attributes can have two sources of variation, namely, natural/common and assignable/special causes, is the basic principle of Statistical Process Control. If variation within a processes’ attributes is within the range of variation from natural or common causes, then that process can be said to have ‘statistical control’. The worker using SPC tracks down some variations that need to be controlled. When variability exceeds the natural cause range, then these should be identified and corrected.

SPC’s value comes from its ability to analyze a process and the causes of variation using objective analysis instead of opinionated reasoning and allow these causes to be measured numerically. Problems that occur within production can then be identified and fixe, reducing waste and total production time, as well as the probability that defects can ever reach the customer. Other quality control methods such as inspection, which use resources to find and fix problems only after production, would seem inferior to these kinds of methods. Moreover, since there is a smaller chance that a product will have to be reworked, the whole production process’ precision is improved.

The SPC is a valuable instrument in maximizing the amount of valuable information that you can use in making critical management decisions. SPC methods provide further understanding of your business’s baselines, positive insight for improving your processes, value communication, and process results. SPC gives you analyses in real time so that you can easily establish controllable baselines for your processes. SPC provides objective and logical analysis instead of making subjective, opinion-based decisions so that you can readily control processes, set and improve the capabilities of your processes and focus your business on the areas that need to be improved upon.

In spite of these benefits, SPC provides merely a tool to identify variation sources within the manufacturing process, and cannot stand alone. It is the worker’s responsibility to take note of variation within production and take necessary measures; positive changes in the production line should be included fully into the system, otherwise eliminated. One primary method of SPC is the implementation of control charts. Two control plans can then be utilized, namely ‘variable information control plans’, which measures the defect’s length, weight, or width, and ‘attribute information control plans’, which counts the number of faulty objects. The latter is the more practical choice, since it precisely determines variations within production. First, the control chart should be set up, to confirm that the process is being analyzed. Next, identify the procedure that you wish to inspect. Then collect the data from the process and plot the data on the control plan. Finally, interpret the control plans to determine whether the process is controlled or not. The worker can then take action based on the results of the control plan.

When using Statistical Process Control methods, a few things should be remembered:

- Do not assume which control plans the processor programs are using and train the workers at using and implementing the Statistical Process Control

- You should always consider conducting a process ability study

- For precise results, use the correct type of control plan for the process you are studying

- Use random tests in analyzing your process, or use a sample size to identify changes in the procedure

- Management charts should not have requirement limits

- Review your control plans on a shop floor from time to time with the workers

- Don’t use control charts just to please your customers

- Do not plan the control chart data after the process has begun

Using Statistical Process Control

Statistical process control (SPC) may sound like such a complicated term, but simply put, it is the application of methods in statistics to the monitoring and evaluation of processes to make sure that it meets its full capacity of producing a product that conform to quality control criteria. What happens under SPC is that a process will be made to behave in a predictable way in order to manufacture a product that is as up to standards as possible while making the least waste possible.

SPC is most frequently used to evaluating and keeping manufacturing lines in check, but it can be equally applied to any process that produces a measurable output. Statistical process control usually makes use of a control chart. This chart is known as a process-behavior chart, or Shewart chart, named after the person who pioneered the process, American physicist, statistician, and engineer Walter Shewhart. He was the one who came up with the control chart and the idea of keeping a statistical control. He used pure mathematical theories of statistics. From these seeds, SPC has come to be used to check whether the given business or manufacturing operational process is within a state of statistical control. The advantages of SPC include the following:

1. Continuous improvement is a goal that SPC strives to achieve. This is simply a continued effort to enhance products, processes, or services, which can come in incremental stages or a possible one-time breakthrough. Design of experiments is also a critical tool used in this process, which helps tell whether any variation has to be allowed, or if there is a certain level of control that can be reached for the particular experiment.

2. SPC works best in examining processes and checking the sources of variation for those particular operations, making use of tools that emphasize objective results over subjective perspectives. This objectivity means that data need to be stated in numerical terms. Variations in the operation have the capacity to affect the output, which means it takes these into account and they are considered vital in terms of being detected and possibly corrected in all possible means. This results in an overall reduction of waste, as well as avoiding passing on some of the potential problems to the end-user.

3. In addition, SPC emphasizes early detection of problems as well as prevention of them, making it a good tool over other quality-control methodology. For example, physical inspection will only be able to find problems and correcting them after they are already in place.

4. Not only does SPC reduce waste, it also saves time in terms of how long it takes to produce a certain item or service. This is largely due to the lower chances of a final product needing to be remade, as well as SPC being able to detect bottlenecks and other possible causes of delay throughout the production line. Identifying these allows the company to reduce them significantly, resulting in huge reduction of costs and a higher customer satisfaction.

Once you understand the benefits that statistical process control can offer your company, you can be sure that your overall operations will be greatly improved and made faster. Your manufacturing line will also be able to speed up its process, reduce costs, and offer greater satisfaction to your customers. With the existence of many consultants that are able to help your business with applying this system, you will not even have to be an expert in statistics, as long as you appreciate the benefits it offers. All you need to do is point out the processes you want to be subjected to the test, and you can rest knowing you will wind up with an improved production line.

Four Considerations for Improving Quality Using Statistical Process Control (SPC)

1. Value / worth:

How a quality can be defined?

Each and every people have different idea and thought about quality. Few will think that quality refers to satisfying the customer, and some other people will say the quality is goodness. So quality differs from each people mind set. So the exact explanation of quality is can be defined as follows:

The quality is that group of inborn characteristic that fulfills the needs.

What is Statistical Process Control where it can be used?

Statistical Process control is simply referred as Statistical Process Control. In order to represent and to understand the performance of the product this SP control is important. The ability of the process can be measured by establishing the requirements. These requirements can be established with the help of Statistical process. We are able to decide whether a method / process suits for the proposed specification or not with the help of process capability.

2. Establishing the SPC

If the quality is improved in a system, then it is obvious that it will lead the system in high range so as to get appraisal. Most of the system gets failed because they won’t confirm that the product is working properly after finishing the product. So this system has to be reprocessed and it needs rework to convert the product into good / conform condition. This is an extra work and the time; money is wasted in huge amount. To avoid this situation the best method is prevention. The error can be identified early and the necessary steps to correct these errors can be taken by this prevention process. If you are using a prevention system then the activities like defects finding and fitting the defect is not needed.

In what way SP control will help?

To avoid non conformance this Statistical Process Control will closely examine them. This SP control process will not only help to monitor the process but also it correctly identifies the fault before the delivery of the product. The reoccurring problems are eliminated quickly.

3. Establishing presentation standards

This defines how for your product is right? These standards will leave the employee to think that non conformance is essential and they accept it. You are able to get a product with Zero defects by comparing process specification and capability, this is done by SP control process. The non conformance frequency is reached zero by using the SP control process.

4. Quality and process depth

More amount of money is needed is wasted in almost all industry because they are failed to correct the faults in developing the product at first time. To reduce the cost and to increase the share market rate, non conformance elimination is the best choice. Therefore using this Statistical Process Control in an organization will help to reduce the faults and prevent loss of money, time that is wasted in manufacturing. Now this system is improved with latest terms so that its benefits are further increased.