The automation control plays a vital role in attaining success for any kind of business. When you supply your first products with good quality and efficiency then the demand for your product increases automatically when it comes into the market and you start getting larger number of orders, at this point of time you need to increase the productivity in a large number so automation is required at any cost. The automation engineers are capable enough to improve the quality and efficiency of a product by using various techniques and equipment in developing an integrated system of hardware and software components and as they being the experts in program development and operating system can control the software side of the industry also but how many engineers can you recruit to carry each and every application accurately.

Therefore, keeping this in mind the technology has become a little more advanced and has bought the industrial robots into existence. These robots are more persistent, fast, reliable and powerful than humans. They can perform any kind of job you require when they are programmed perfectly. The ISO has defined industrial robot as “an automatically controlled, reprogrammable, multipurpose manipulator”. Which means these robots can perform multifunctional tasks and can be controlled by you as you want it to be by changing its program according to your requirement. Robotic Automation Systems can perform continuously for years along with providing accurate results for the programming function that you have loaded into it as per your industries specific requirements. In this way they can meet the standards of quality manufacturing. Usually the life span of an industrial robot is 12 to 16 years.

Robotic Automation Systems

These robots can be classified into three different types depending on their mechanical structure. Firstly the Gantry robot, they are fixed and work with a rectangular work envelope and they mainly perform ‘pick and place’ actions. Secondly the SCARA (Selectively Compliant Articulated Robot Arm) robots having four axes of motion, moving with x-y-z co-ordinate circular envelope and are used for factory automation. Thirdly, Articulated robots which have interactive rotary joints ranging from two to ten, these are generally used for welding, painting and assembly purposes.

The industrial robots can also be used with different additions such as ‘End effectors’ which are the end of arm tooling attached to robotic arms; they can interact with and sense the external environment. The ‘optical system’ refers to the vision system of robots, they are designed according to the digital input/output devices and it mainly performs the inspection of the products. ‘Motion controllers’ are needed to move the robots and position them smoothly and accurately.

Therefore, the industrial robots are the best alternative for those manufacturing owners who are unable to handle the employee’s emotional and mental excuses for not completing the work on time and want to accelerate the manufacturing of goods by continuous production along with quality assurance.

The importance of automation and robots in all manufacturing industries is growing. Industrial robots have replaced human beings in a wide variety of industries. Robots out perform humans in jobs that require precision, speed, endurance and reliability. Robots safely perform dirty and dangerous jobs. Traditional manufacturing robotic applications include material handling (pick and place), assembling, painting, welding, packaging, palletizing, product inspection and testing. Industrial robots are used in a diverse range of industries including automotive, electronics, medical, food production, biotech, pharmaceutical and machinery.

The ISO definition of a manipulating industrial robot is “an automatically controlled, reprogrammable, multipurpose manipulator”. According to the definition it can be fixed in place or mobile for use in industrial automation applications. These industrial robots are programmable in three or more axes. They are multi-functional pieces of equipment that can be custom-built and programmed to perform a variety of operations.

Industrial Automation Supply

The major advantages of industrial robots is that they can be programmed to suit industry specific requirements and can work continuously for years, consistently meeting high manufacturing quality standards. The economic life span of an industrial robot is approximately 12-16 years. Due to their persistent accuracy industrial robots have become an indispensable part of manufacturing.

Industrial robots are classified into different categories based on their mechanical structure. The major categories of industrial robots are:

- Gantry (Cartesian) Robot: They are stationary robots having three elements of motion. They work from an overhead grid with a rectangular work envelope. They are mainly used to perform ‘pick and place’ actions. Gantry robots have all their axes above the work making them also ideal for dispensing applications.

- SCARA Robots: (Selectively Compliant Articulated Robot Arm) These robots have 4 axes of motion. They move within an x-y-z coordinated circular work envelope. They are used for factory automation requiring pick and place work, application and assembly operations and handling machine tools.

- Articulated robots: An articulated robot has rotary joints. It can have from two to ten or more interactive joints. Articulated robots are well suited to welding, painting and assembly.

Basic industrial robot designs can be customized with the addition of different peripherals. End effectors, optical systems, and motion controllers are essential add-ons. End effectors are the end-of-arm-tooling (EOAT) attached to robotic arms. Grippers or wrenches that are used to move or assemble parts are examples of end effectors. End effectors are designed and used to sense and interact with the external environment. The end effectors’ design depends on the application requirements of the specific industry. Machine Vision systems are robotic optical systems. They are built-on digital input/output devices and computer networks used to control other manufacturing equipment such as robotic arms. Machine vision is used for the inspection of manufactured goods such as semiconductor chips. Motion controllers are used to move robots and position stages smoothly and accurately with sub-micron repeatability.

Industrial robots fill the need for greater precision, reliability, flexibility and production output in the increasingly competitive and complex manufacturing industry environment.

Top 7 Best Industrial Automation & Control Systems Companies:

OT

Open Technologies offers services in industrial automation field. We work with a wide range of customers from Moscow and other Russian cities, as well as Belarus, Uzbekistan, Switzerland.

- Automatic control systems (ACS)

- Automatic Dispatch and Technological Control System (ADTCS)

- Automated information and measuring systems (AIMS) (for power energy, heating energy, gas, water supply, sewage)

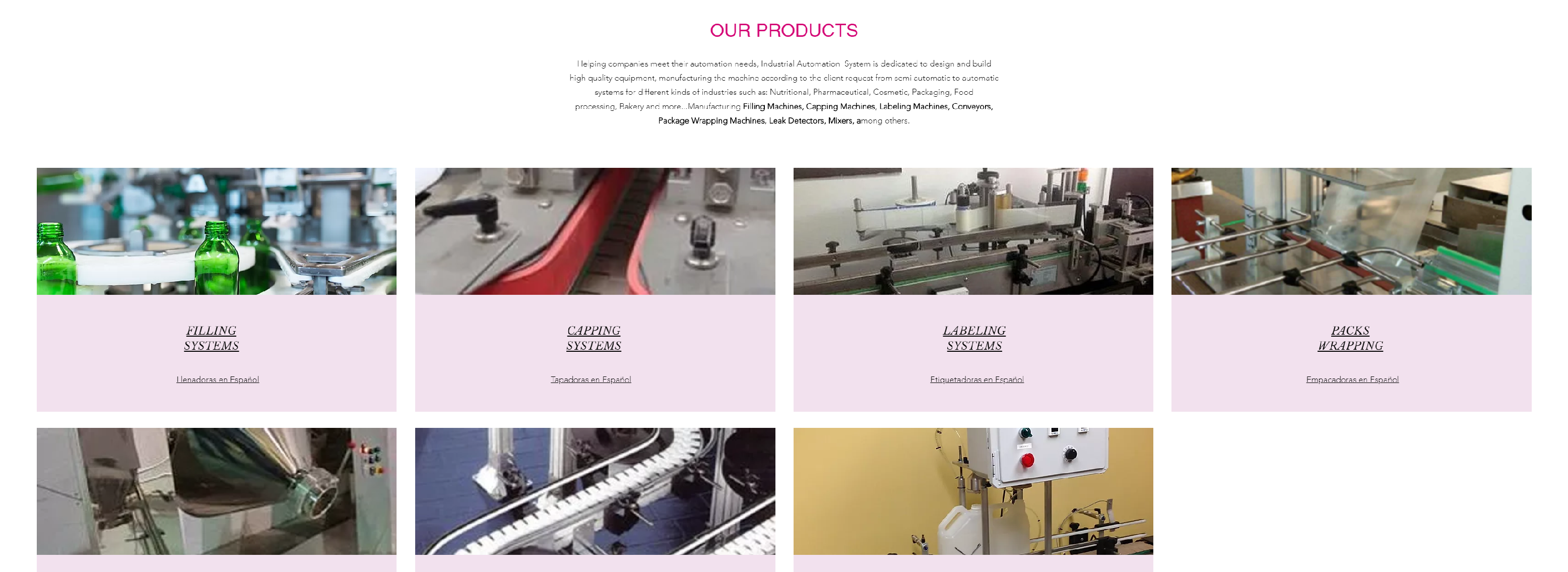

INDUSTRIALAUTOMSYSTEM

Helping companies meet their automation needs, Industrial Automation System is dedicated to design and build high quality equipment, manufacturing the machine according to the client request from semi automatic to automatic systems for different kinds of industries such as: Nutritional, Pharmaceutical, Cosmetic, Packaging, Food processing, Bakery and more…Manufacturing Filling Machines, Capping Machines, Labeling Machines, Conveyors, Package Wrapping Machines, Leak Detectors, Mixers, among others.

- Filling Systems

- Capping Systems

- Labeling Systems

- Packs Wrapping

- Mixers

- Сonveyor systems

- Leak detector

- Auxiliar Equipment

EPICINDUSTRIALAUTOMATION

EPIC is a complete automation services company for intelligent control system design and complete automation system integration.

ASCONLINE

Automation Systems and Controls specialise in automation engineering services and electrical automation equipment.

- Increasing throughput by eliminating nonconforming parts

- Improving quality by verifying all parameters of an item

- Tracking products to ensure items are where they need to be

- Industrial grade with a library of advanced 2D and 3D vision tools

- High speed image acquisition and processing

- Exceptional application and integration flexibility

- Reduce Costs

- Increase throughput

ABB

ABB is a pioneering technology leader that works closely with utility, industry, transportation and infrastructure customers to write the future of industrial digitalization and realize value.

Products:

- Control Room Solutions

- Communication Networks

- Drives

- High Voltage Products

- Low Voltage Products and Systems

- Measurement and Analytics

- Mechanical Power Transmission

- Medium Voltage Products

- Metallurgy Products

- Motors and Generators

- PLC Automation

- Power Converters and Inverters

- Robotics

- Semiconductors

- Substation Automation, Protection and Control

- Transformers

Systems:

- Control Systems

- Electric Vehicle Charging Infrastructure

- Enterprise Software

- FACTS

- Grid Edge Solutions

- HVDC

- Marine Vessels

- Network Management

- Operations Management Software

- Power Consulting

- Power Electronics

- Safety

- Substation Automation, Protection and Control

- Substations and Electrification

- Turbocharging

- UPS and Power Conditioning

EMERSON

Automation Solutions from Emerson can transform your manufacturing process and control operations.

- Measurement Instrumentation

- Valves, Actuators and Regulators

- Control and Safety Systems

- Fluid Control & Pneumatics

- Electrical Components and Lighting

- Solenoids and Pneumatics

- Services Consulting

- Operations and Business Management

- Asset Reliability

SE

As a global specialist in energy management and automation in more than 100 countries, we offer integrated energy solutions across multiple market segments.

- Digital Transformation

- Scalable IT Infrastructure

- Evolution of Mobility

- Safety and Security

- Sustainability