Manufacturing analytics software is a tool that manufacturing companies use to collect, process and analyze data generated during the production process. The software combines data from various sources, including sensors, machines, and systems to provide in-depth insights into manufacturing operations. It helps manufacturers to understand, monitor, and optimize their production process, leading to greater efficiency and productivity, reduced downtime and waste, and improved product quality.

This software is designed to provide real-time, actionable insights to manufacturing plant managers, production supervisors, and operators. It collects data from manufacturing systems such as enterprise resource planning (ERP), manufacturing execution systems (MES), and supervisory control and data acquisition (SCADA) systems. It also collects data from other sources, such as sensors, algorithms, and artificial intelligence (AI) programs, to provide a comprehensive view of the manufacturing process.

Manufacturing analytics software performs various data analysis tasks, such as data cleansing, aggregation, normalization, and modeling. It also employs various analytical techniques, including statistical analysis, predictive modeling, and machine learning. These techniques help to identify patterns, trends, and anomalies in the data, which can be used to optimize production processes.

One of the critical features of manufacturing analytics software is real-time monitoring of the production process. It monitors the performance of machines, equipment, and processes, and alerts operators and supervisors in case of deviations from the normal operating range. The software also provides real-time information on the production process, allowing operators to identify and address issues in real-time, thus minimizing the risk of production downtime.

Manufacturing analytics software provides insights into various manufacturing process parameters, such as production output, scrap rates, cycle times, downtime, quality, and resource utilization. These insights allow production managers to optimize the production process, reducing costs, improving quality, and increasing productivity.

The software also provides insights into the predictive maintenance of machines and equipment. It collects data from sensors, and machine log files to identify the health status of machines and equipment. This insight helps production managers to schedule maintenance on machines and equipment proactively, reducing downtime and increasing the life of the machines.

Another critical feature of manufacturing analytics software is the ability to perform root cause analysis. It identifies the cause of production issues, such as quality defects, machine breakdown, and delays in the production process. The software analyzes the data from various sources to identify the underlying issues, and provide recommendations on how to address them.

Manufacturing analytics software is an essential tool for manufacturing companies looking to optimize their production processes. It provides deep insights into production data, helping production managers to identify areas for improvement and optimize the production process. With this software, manufacturers can improve productivity, reduce downtime and waste, and improve product quality.

ALTERYX

The Alteryx Analytics Automation Platform delivers end-to-end automation of analytics, machine learning, and data science processes that accelerate digital transformation.

- Data Preparation and Blending

- Advanced Analytics

- Predictive Modeling Deployment

- Event Triggering

- Analytic Apps

MATICS.LIVE

Collect, analyze and collaborate in real time to gain production efficiency. Matics is the new way to manage your production floor.

- Multi-Source Data Aggregation

- Real-time Analysis and Prediction

- Advanced Visualization Capabilities

- Work management tools

- Structural Communication and Notifications

- Task and Process Automation

SAS

Manufacturing analytics software from SAS helps you stay nimble and unlock potential by analyzing data to reduce costs, improve productivity and minimize risk.

- Manufacturing Quality

- Connected Factory

- Warranty Cost Reduction

- Supply Chain Optimization

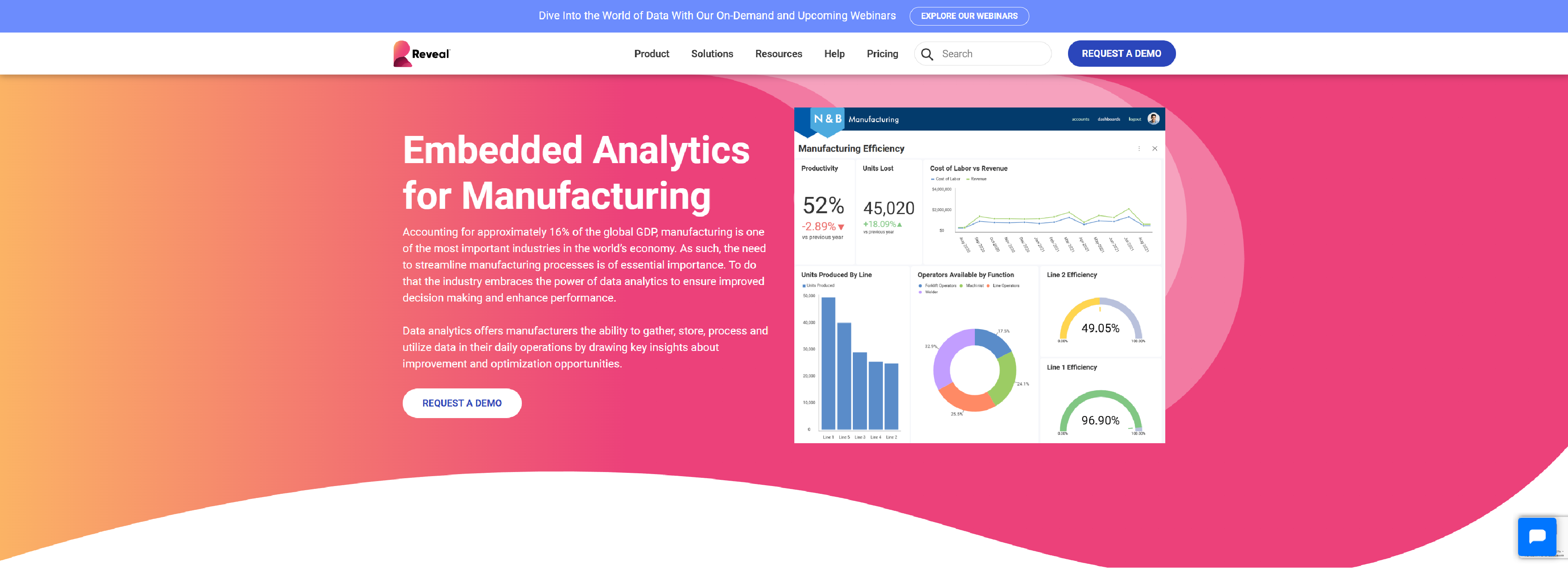

REVEALBI

The manufacturing analytics software by Reveal brings predictive analytics, big data, IoT, and mobile-first design to manufacturers and allows them to create insights rich dashboards in no time.

- Forecasts market demand

- Greater customer service

- It’s cost effective

- Increases operational efficiency in the manufacturing processes

TAVANT

Tavant manufacturing analytics platform TMAP is an AI-enabled platform designed for Manufacturers (OEM) to find the areas of improvement & helps in controlling the cost.

- Warranty Reserve Analytics

- Suspect Claim Analytics

- Quality and Reliability

- IoT Analytics

- Warranty Analytics

- Code Predictions

- Service Contract Analytics

- Service Parts Management

- Dealer Certification

- Intelligent Search

- Field Service Analytics

- Warranty Cluster/Peer Averaging Analysis

SISENSE

Increase productivity and profitability with complete visibility into all your manufacturing data.

- Connect data and operations with IoT

- Streamline sales and operations planning

- Combine supply chain and logistics

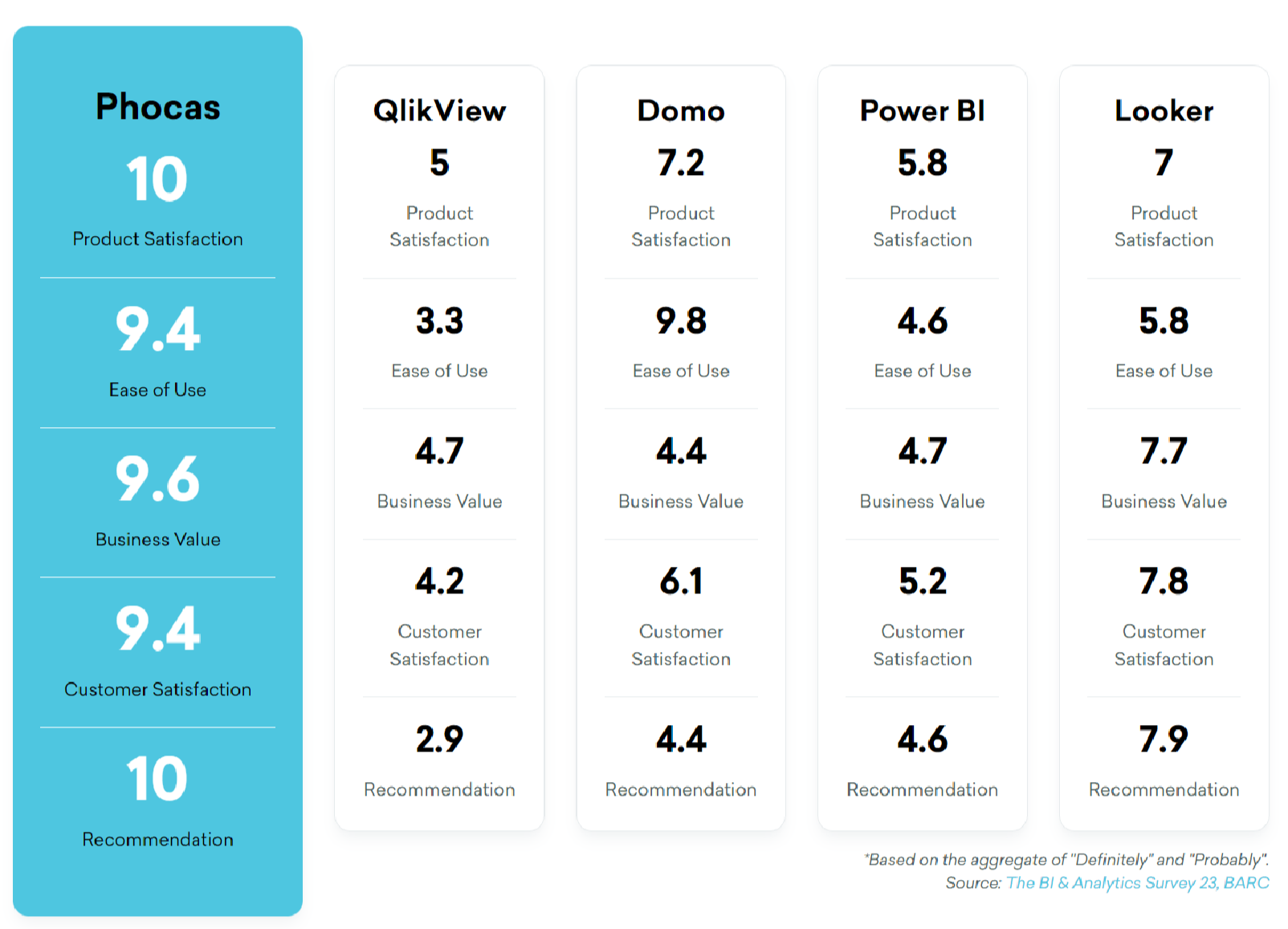

PHOCASSOFTWARE

Phocas Software offers Manufacturing Data Analytics Software & Metrics to simplify data & reduce the time to deliver insights. Enabling manufacturers to manage business more efficiently. We also offer Manufacturing Analytics, Data Analysis, Reports, and Dashboards for Manufacturers.

- Get the data you need, the way you need it

- Manage your supply chains quickly and efficiently

- Reliably track the critical metrics that power your success

CIMLOGIC

Cimlogic’s manufacturing analytics solutions are designed to collect and analyse data from appropriate sources to identify areas for improvement.

- Increase productivity and performance

- Connected supply chain

- Data-driven decision making

- Sustainability

- Embrace digital in manufacturing

FOURJAW

FourJaw provides manufacturing analytics software by capturing real-time data via our machine monitoring platform.

- Grow Productivity And Profitability With Our Machine Analytics Tool

- Overcome Challenges & Unlock Opportunites

- Drive Efficiency And Increase Productivity

- Plug & Play Machine Monitoring System

KNIME

Create data science solutions with the visual workflow builder, & put them into production in the enterprise.

- Forecast demand and optimize inventory with clear insights into changing customer behavior

- Improve process and product quality by automating monitoring, tracking, and reporting

- Supercharge product R&D with a feedback loop driven by customer and operational insights

- Reduce costs related to equipment failures with predictive maintenance

SEEQ

Seeq’s machine learning powered advanced analytics software provides trending, pattern recognition, and predictive analytics for time-series based process data.

- Connect to all of your data

- Flexible and extensible

- Actionable insights in minutes

AISCORP

Aegis Software enables industrial manufacturing excellence by improving control and visibility with an adaptable MES system built on an IIoT backbone.

- Easy Creation of Operational KPIs, Improving Performance

- Use Any BI Solution to Achieve Situational Awareness Across Factories

- For When You Don’t Know What You Don’t Know

- Empower Those Who Need the Reports to Easily Make Their Own

- Automate Report Generation and Delivery

- The Complete Process, Product & Materials Traceability Record

- Benefit from Automated Proactive and Early Warnings

SHOPLOGIX

Shoplogix Smart Factory Suite makes it easy for you to connect, collect, analyze and action on your manufacturing data.

DATAPARC

Improve your facility’s decision making and troubleshooting capabilities with real-time industrial process data analytics tools.

- Get Connected

- Dive Into The Data

- Produce Answers. Faster.

- See The Big Picture

- Put It In Context