A warehouse management system, abbreviated as WMS and sometimes referred to as warehouse management software or a warehouse management solution, is one of the most essential parts of a warehouse’s smooth operation.

The systems, which come in many shapes, sizes, and forms, all perform the same basic functions. The most primary function is controlling the storage and movement of materials, products, and items within the warehouse. In a very basic sense, they track inventory.

A warehouse management system isn’t only focused on tracking the location of inventory within a warehouse though. It also tracks transactions which involve the inventory like shipping, receiving, put away, and picking. But how exactly do warehouse management systems work? If you’ve never seen one in use before, then they can be slightly confusing.

The first thing to know if that warehouse management systems are completely computerized these days. A central computer stores and interprets data sent to it from mobile systems. The mobile systems include electronic tools like mobile computers, barcode scanners, wireless LANs, and other pieces of technology that use Auto ID Data Capture technology. Some of the most advanced systems use Radio-frequency identification to quickly transmit data to the central computer.

Let’s look at a quick scenario to help better understand how a warehouse management system works:

An employee is given the task of putting away new stock on a rack in the warehouse. Whenever they put a product onto the rack, they scan it with a barcode scanner. They also scan an ID piece on the rack. They do this with each item.

The information from the barcode scanner is sent instantaneously through a real-time wireless transmission to the central computer. Information can be sent from dozens of barcode scanners being used by dozens of different employees at the same time.

The central computer processes the data and creates a map of where the new stock is located in the warehouse. This makes accessing the stock extremely easy. For instance, when an order is placed, an employee can simply perform a search in their warehouse management system and it will tell them where the product is kept in the warehouse.

Once the employee finds the product and takes it out for shipping, the warehouse management system notifies the central computer of the fact via wireless transmission. The central computer makes a note that the item was sent to receiving and thus keeps an accurate inventory of everything in the warehouse.

The central computer’s database can also create reports, graphs, and the like that can be used by supervisors and managers to survey the status of the goods in the warehouse.

Warehouse management software systems are very important to the well-being of many companies, especially those with busy warehouses. They are also a key piece of a number of company’s supply chains and logistics. Though understanding such a system is far from a five-minute task, the above information will give you a solid basis for learning more on the systems.

Save Money:

Warehouse management software will save you hundreds if not thousands of dollars by making your warehouse inventory and shipment of products well managed. Using ideal software for warehouse management has been behind the success of most multi-million dollar businesses and you too could make it to the top by using warehouse management solutions ideal for your business needs.

- Save money from the time you make inventory and reports of your resources. Materials, machinery and manpower will be appropriated for projects and production comprehensively you will never miss out on any important item. You will literally save time and money by investing in warehouse management software that will take care of all inventories for you. You will also be able to send reports right away about replenishing your inventory should you need to.

- You save money when items in your warehouse are all placed in ideal locations. For example raw materials needed to manufacture products must be placed in efficient places like raw materials for food and beverages otherwise these would spoil and cost you money in re purchasing raw materials.

- You will be able to save money by using this type of software to store finished products more efficiently. Products that are ready to be delivered to customers need to have a suitable place where they can be stored until they are to be shipped out of the factory. You will be able to monitor products and house these securely; you can even integrate software for warehouse management with your security system to totally reduce the risk of problems with the safety of your department.

- You will save money and time by monitoring dwindling resources needed in manufacturing. You can make an estimate using this management software and create orders for raw materials right away. There is no time to waste; your production or manufacturing line will never be interrupted in case you need to reorder materials.

- You will be able to monitor maintenance of machinery which is essential in factories and manufacturing plants. Without sufficient and regular maintenance, expensive machines will break and your production line interrupted costing you money. You need software for warehouse management to control these situations and help you make schedules of maintenance and repair of machines and systems in your factory.

- You will never need to worry about employing people needed to make regular inventory of your materials and supplies when you use warehouse management software and of course you will also save money by integrating this software to your company’s ERP system for fast response for any warehouse management concerns and faster delivery of your products to customers.

Finally, your customers are the lifeblood of your business. When your warehouse is in order you will be able to manufacture products more efficiently eventually increasing customer satisfaction. This will increase your sales and increase your revenue in the process. Your brand will soon be recognized not just locally but internationally for having impressive standards in quality and efficient delivery.

ASAPSYSTEMS

![]()

Optimize inventory, increase productivity, and improve traceability with barcode inventory management software and asset tracking system. Get a no obligation trial today!

Features:

- Kitting

- Offers Real-time monitoring

- Maintain Standard Inventory Cost

- Records All Inventory Issued by Location

- Single Warehouse or Multiple Warehouses

- Mobile Computing

- Track All Inventory Received

- Receive to a Default Location or to a Scanned Location

FOXFIRESOFTWARE

Foxfire warehousing software is ideal for mid-sized warehouses. Foxfire WMS software has competitive pricing and is a full featured Warehouse management system.

Benefits:

- Set up a new warehouse

- Get control of inventory

- Track labor expenses

- Minimize employee theft

- Avoid missed shipments and customer chargebacks

- Reduce risks

MAGAYA

Innovative supply chain and logistics software from Magaya gives you and your customers a competitive advantage.

- Control and manage cargo and inventory before it arrives and in the warehouse

- Use the warehouse tracking software to define locations and set default receiving locations for inventory

- Combine with WMS Mobile scanning for inventory counting, fast pick & load, and more

- Automate billing for storage and define charge types for cold storage and other specialities

- Give your customers 24/7 visibility with online transaction tracking

SKUVAULT

Track and sync your inventory faster with SkuVault’s cloud-based Warehouse Management System (WMS) .

- Supply Chain

- Catalog

- Inventory

- Pick, Pack, Ship

- Advanced Reporting

- Training & Support

- FBA

COMARCH

Comarch is a global powerhouse specialized in the design, implementation and integration of advanced IT services and software.

- Increased visibility of all activities in the warehouse

- Quantity and quality control of delivered goods

- Automatic identification (AI) by using barcodes

- GS1 standard labels

- Advanced order picking

- Automatic or manual assignment of warehouse locations

- Traceability of batches and expiry date management

- Internal and external inventory stocktaking

- Support for forwarding, shipments and transport

- Integration with carriers

GRANITEWMS

Warehousing Solutions – We’re leader in small and medium business warehouse management system with over 30 sites in SA, Namibia, Zimbabwe and in the UK.

- In a nutshell

- Barcoding at its core

- Functional fit

- Ease of use

- Identification labelling

- Uses Mobile RF Scanning

SAVANNA

Westfalia’s Savanna.NET® Warehouse Execution System (WES) is a unique warehousing solution comprised of a tightly integrated Warehouse Management System (WMS) and Warehouse Control System (WCS) software that conforms to your business processes.

- Order Processing

- Item/SKU and Warehouse Inventory Management

- Container Management

- Security/User Management

MANH

Manhattan Associates designs, builds and delivers supply chain, omnichannel and inventory software so you’re ready to sell and execute in the store and throughout your network.

- Auditor-approved, cycle-counting functionality that eliminate costly physical counts.

- Support for sophisticated warehousing needs, including value-added services, lot management, serial number tracking and product recalls.

- Flexibility to accommodate omnichannel and/or multi-tenant fulfillment.

- Advanced order fulfillment strategies that leverage wave and/or waveless approaches simultaneously.

- Automatic information capture via modern handheld mobile devices, voice recognition and/or seamless Material Handling Equipment (MHE) integration

- Multi-carrier solution sync through native transportation execution capabilities or External Parcel Integration (EPI) framework.

- Native Appointment Scheduling, Guard Check-in and Check-out, Dock Door Management and Yard Management functionalities that increase visibility, security, and throughput.

- Slotting Optimization and Labor Management modules that improve product placement and employee performance.

- Streamline inventory receiving processes with cross-docking, quality audit and vendor performance.

SNAPFULFIL

Snapfulfil is a Tier 1 Software as a Service (SaaS) cloud warehouse management system (WMS) with no capital expense, a 45 day implementation and rapid ROI.

3PLCENTRAL

3PL Central is the premier provider of 3PL Central Warehouse Management Software and online inventory management software that improves warehouse tracking and efficiency including our flagship product 3PL Warehouse Manager.

- Efficient Operations

- 3PL Billing

- Paperless Warehouse

- Complete Visibility

- Serve Your Customers

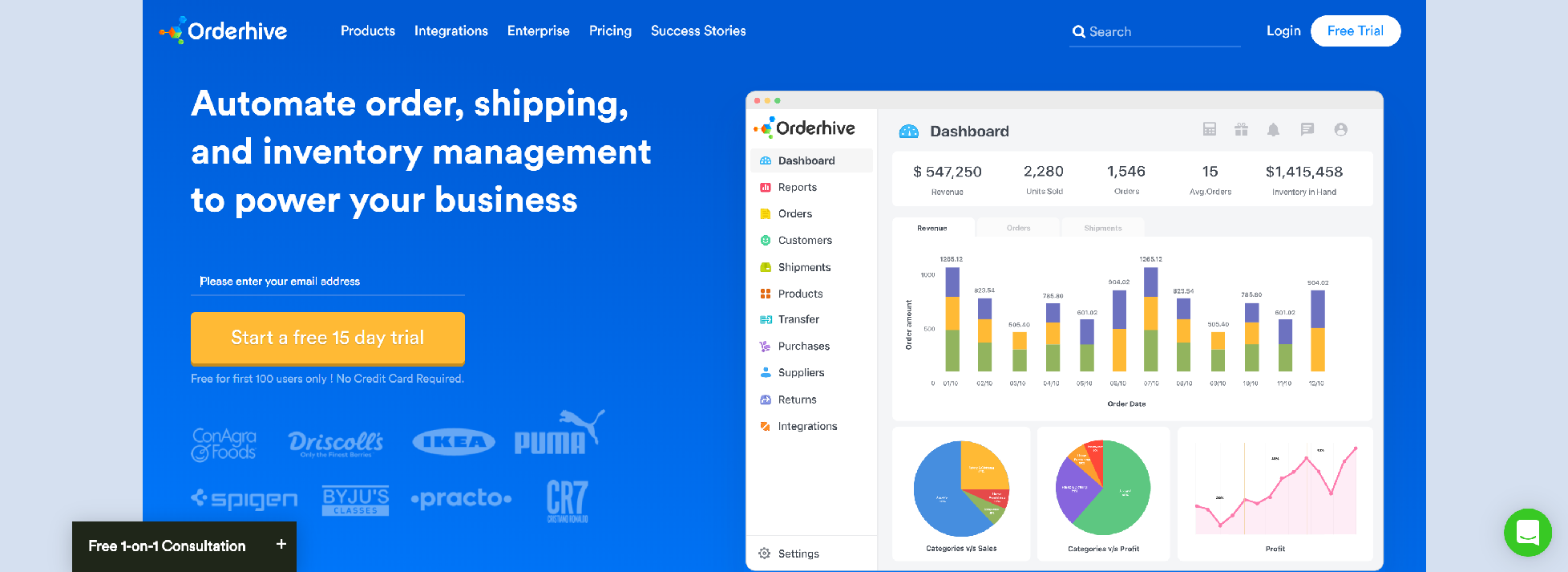

ORDERHIVE

Simple and Powerful Multi-channel Inventory management software to help you track orders, control inventory, create shipments,raise purchases and much more.

- Save inventory holding costs

- Boost productivity with faster picking/packing

- Optimize warehouse resources

- Eliminate paperwork and manual errors

MEADEWILLIS

Supply Chain and Inventory Management Software Solutions for business. Meade Willis is a leading global B2B E-Business and systems integration company.

Benefits:

- Refined Demand Planning

- Increased visibility, Transparency & Traceability

- Maximized Labor Productivity & Optimized Processes

- Reduced Operational & Support Costs

- Improved Security

- Minimal Deployment Footprint

- Eliminate manual entry & data errors

- Highly customizable functions (if required)

- Enhanced customer-supplier relationships

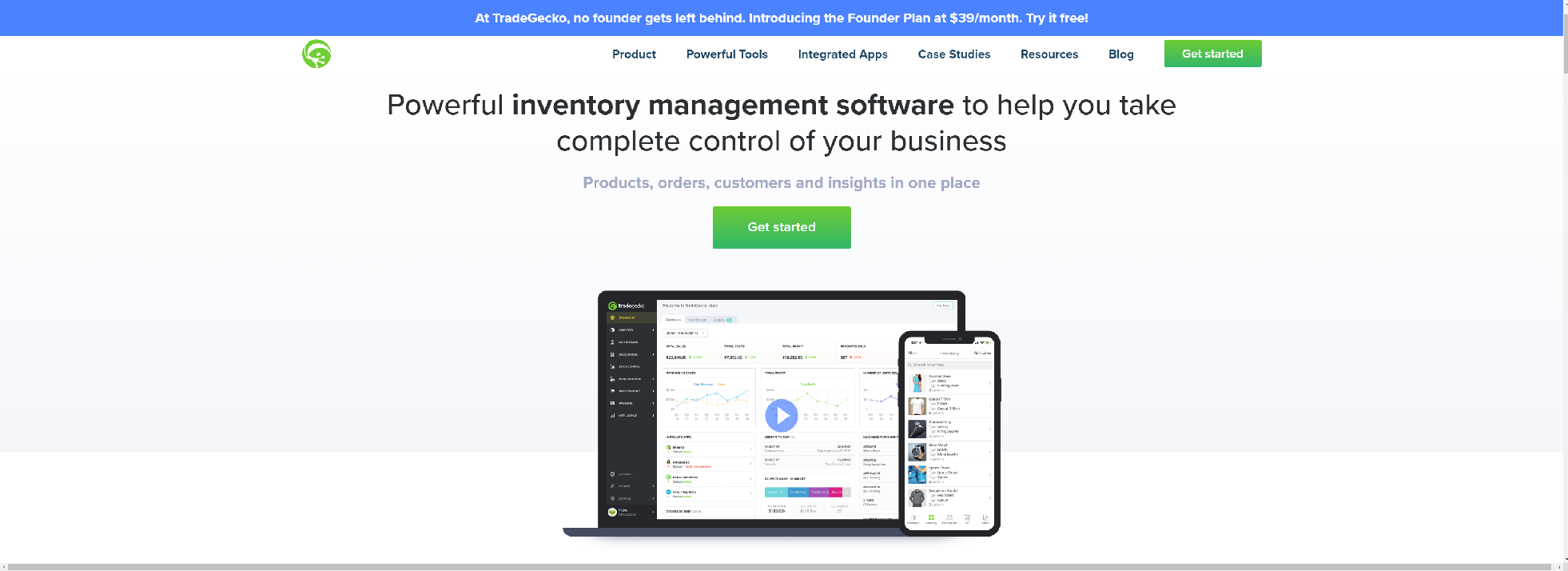

TRADEGECKO

Powerful inventory management software for eCommerce and wholesale with Shopify, Xero, QuickBooks, Amazon, a B2B ordering platform, payments and mobile to take complete control of your business.

- Inventory management meets warehouse operations

- Fast and accurate procurements

- Geo-routing and overflow management