Top 10 Computerized Maintenance Management System (CMMS) Software

A Computerized Maintenance Management System (CMMS) is software that helps organizations manage and streamline maintenance tasks and operations. Its main goal is to keep track of an organization’s equipment, assets, and maintenance activities, ensuring that everything operates efficiently and with minimal downtime.

Discover the Top 10 Best Computerized Maintenance Management System (CMMS) software solutions

Accruent (Maintenance Connection)

Streamline workflows, prevent asset breakdowns, automate essential processes, maintain regulatory compliance, and minimize downtime with the powerful, easy-to-use maintenance management software from Maintenance Connection (Accruent).

- Centralize your documentation, automate tasks, implement secure e-signatures, ensure accurate procedure versioning, and maintain robust audit trails, access reports and streamline workflows to meet regulatory standards, including FDA 21 CFR Part 11 and ISO 27001 compliance

- Integrate seamlessly with EDMS and IoT systems to consolidate data, enhance overall processes, and improve access to accurate, approved asset information

- Boost repair efficiency and reduce costs through optimized spare parts management, labor scheduling, and demand forecasting

- Easily find, purchase, and organize parts to keep assets running smoothly, lower inventory costs, improve availability, reduce repair times, and eliminate obsolete stock

- Enhance maintenance processes, reduce downtime, and extend machinery lifespan by ensuring all activities are executed with the latest procedures and approved documentation

- Adopt a CMMS your team will love! Simplify maintenance with a user-friendly interface that drives efficiency, ensures quick onboarding, and provides fast, anytime access to critical tasks

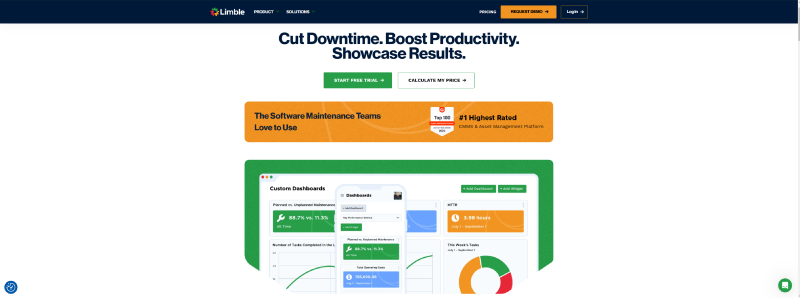

Limblecmms

Limble’s flexible CMMS and EAM software is intuitive, packed with features, and supported by enterprise-level assistance, gain complete visibility and control with a fully integrated maintenance system that scales with your business.

- Track and link your assets to work orders, parts, vendors, and preventive maintenance tasks

- Plan recurring PM tasks, automate scheduling and assignments, and minimize unplanned downtime

- Ensure parts availability with a searchable, filterable parts database and automatic reordering

- Integrate your CMMS with IoT sensors for proactive condition monitoring and predictive maintenance

Fiixsoftware

Fiix is a cloud-based CMMS software that enables you to plan, track, and optimize maintenance through robust integrations, detailed reports, built-in AI tools, and more.

- Eliminate time-consuming, unclear, and ineffective work orders to get the job done faster and keep your assets performing at their best

- Users and guests can submit unlimited work requests through the portal, easily searching, sorting, and tracking them

- Schedule maintenance based on date, time, meter readings, events, or condition triggers

- Attach SOPs, task lists, photos, and suggested parts to work orders, giving technicians quick access to everything they need to complete their tasks

- View all your work orders and key details with just a few clicks, including completion rates, repair dates, total costs, follow-up tasks for failed inspections, and more

- Quickly analyze work order performance with the work order insights report

Getmaintainx

MaintainX helps you manage reactive and preventive maintenance while streamlining the daily operations of your business.

- Transform how teams manage all types of maintenance and gain full visibility into the process

- Provide frontline and back-office workers with an intuitive, user-friendly platform to manage their tasks

- Enhance decision-making with maintenance data—no data analysis experience required

- Cut costs and simplify inventory management by connecting to your ERP system for a comprehensive view of parts across all sites

- Facilitate knowledge sharing, answer questions, and provide clarification whenever needed

Upkeep

The UpKeep Asset Operations Management Platform is a mobile-first CMMS, EAM, and IIoT suite designed to streamline the work order process and transition you from reactive to preventive maintenance.

- Manage maintenance life cycles across multiple locations, ensuring seamless day-to-day operations

- Optimize asset utilization for maximum efficiency

- Gain real-time performance data insights to make informed decisions

- Adopt an ecosystem approach to unify maintenance, reliability, and operations

- Bridge the gap between maintenance, reliability, and operational teams

- Offer an intuitive interface that’s easy for every employee to use

- Reduce maintenance response times for faster resolutions

- Streamline communication with unlimited free requesters for enhanced collaboration

- Decrease equipment and asset downtime by up to 26%

- Ensure consistent and accurate cost tracking

- Extend the lifespan of assets and equipment by up to 11%

- Achieve up to 652% ROI by integrating UpKeep into your workflow

- Eliminate paperwork and enjoy seamless collaboration with real-time work order updates across locations

- Access vital information instantly, with complete asset histories from maintenance logs to warranties and depreciation details

- Make data-driven decisions using real-time data and advanced analytics to optimize asset performance

- Track assets in real-time with wireless sensors, taking preventive maintenance to the next level

- Simplify equipment maintenance scheduling to stay ahead of needs

- Set alerts to ensure the right parts are always available when needed

- Gain clear visibility into maintenance costs for better financial control

- Automate recurring work orders based on specific time intervals (day, week, or month)

- Create automated PM schedules based on machine cycles, vehicle mileage, or other metrics

- Filter work orders by technician, location, due date, status, or priority level

- Automatically generate work orders and notify technicians via mobile push notifications when assigned

- Attach PDFs of equipment manuals and instructions directly to work orders for easy reference

- Enhance accuracy with photos or videos added to work orders

- Assign work orders based on priority and location from both desktop or mobile devices

Emaint

Introducing eMaint, the innovative CMMS, EAM, and IIoT software from Fluke Reliability, this cloud-based ecosystem seamlessly connects hardware and software, empowering you to enhance uptime, improve reliability, and optimize production.

- Simplified asset management, comprehensive maintenance records, and effective lifecycle planning

- Organized, user-friendly work order management, work requests, and preventive maintenance scheduling

- Manage spare parts, track inventory, and improve Mean Time to Repair (MTTR)

- The eMaint mobile app connects teams across the factory floor, the field, or even when working offline

- Integrate your CMMS with 1000+ apps, ERPs, SCADA, PLC systems, and more

- Easily create dashboards and reports with eMaint, uncover growth opportunities, and showcase success to leadership

- eMaint is a multi-site CMMS tailored for global, enterprise-level businesses managing maintenance across multiple teams and locations

- eMaint’s condition monitoring is a cloud-based solution that enables everyone, whether novices or experts, to track assets and predict faults or failures

- Standardize best practices, streamline audit preparation, and optimize digital record-keeping for compliance

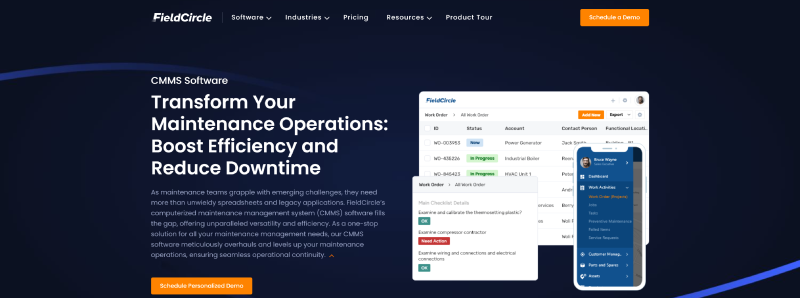

Fieldcircle

FieldCircle’s CMMS software bridges the gap, providing unmatched versatility and efficiency. As an all-in-one solution for your maintenance management needs, our software transforms and elevates your maintenance operations, ensuring smooth and continuous operations.

- Work Order Management

- Preventive Maintenance

- Scheduling & Dispatch

- Customer & Location Management

- Asset & Equipment Management

- Vendor Management with RFQ and PO

- Parts and Inventory Management

- Time Tracking and Timecards

- Contract and SLA Management

- Invoice Management

- Checklist Template Management

- QR Code Labeling and Scanning

- Reports and Dashboards

- Technician, Crew, and Contractor Management

Micromain

Micromain CMMS helps you optimize maintenance processes and simplify inventory management to achieve peak performance.

- CMMS simplifies the scheduling and tracking of work orders, ensuring smooth assignment and monitoring of labor, parts, tools, and critical details

- Enhance maintenance with our CMMS, creating a solid plan to improve performance and safety

- Manage assets efficiently with our CMMS, allowing you to set up and track an unlimited number of assets, organized into effective groups

- Optimize parts and inventory management with our software, automatically updating inventory levels as parts are used

- Our efficient CMMS provides accurate time tracking for technicians as they complete tasks

- Print and attach QR codes to assets for seamless digital integration, enabling direct access via QR code reader to request work orders

Maintenancecare

Maintenance Care CMMS is a robust facility maintenance and management software designed to keep your building and assets operating smoothly.

- Create custom fields by selecting from various question types

- Design custom forms and attach them to any work order

- Link forms to groups of rooms, users, assets, etc

- Access everything directly from the mobile app

- Easily generate reports for all custom fields

- Automatically assign tasks to team members in advance

- Quickly adjust task frequency, time of day, and assignment responsibilities

- View a comprehensive calendar of all scheduled work orders, inspections, and tasks

- Attach training materials, reference documents, videos, and other files to each task

- Plan ahead to improve safety and reduce equipment failures

- Ensure all your reading points are correctly placed

- Track temperature trends for each sensor point and visualize or export the data

- Receive email or text alerts when readings exceed or fall below the desired temperature range

- Choose from a variety of plug-and-play sensor types

- Prevent issues like overheating, food spoilage, or uncomfortable room temperatures

- Enable visitor pre-check-in on mobile devices or computers

- Use QR codes or the OneAccess Kiosk App on a tablet for check-ins

- Create a quick and convenient express check-in process for employees

- Digitally track and log all visitors entering and leaving your facility

- Maintain health and safety protocols with touchless entry

Ifs

IFS Ultimo offers even more with EHS modules, purchasing capabilities, an autonomous maintenance module, financial management tools, and a wide range of integrations.

- With IFS Ultimo and CMMS software, you can take a more proactive approach, shifting towards condition-based and predictive maintenance

- We offer three editions to help you professionalize asset management, featuring various (preventive) maintenance tools, inventory management, contract management, mobile access, reporting, and much more!

What Are the Types of CMMS?

Cloud-Based CMMS – Cloud-based CMMS is hosted on the cloud and accessed via the internet. This type of system eliminates the need for on-premise servers and allows for remote access from any device.

On-Premise CMMS – On-premise CMMS is installed on local servers and maintained internally by the organization’s IT team.

Mobile CMMS – Mobile CMMS provides access to the software through mobile devices (smartphones, tablets), enabling maintenance workers and managers to access information on the go.

Enterprise Asset Management (EAM) – EAM software is an advanced version of CMMS, typically used for managing the entire lifecycle of physical assets across the organization, not just maintenance tasks.

Work Order Management Systems (WOMS) – A type of CMMS focused primarily on creating, tracking, and managing work orders.

Predictive Maintenance CMMS – Predictive maintenance CMMS integrates with IoT sensors and analytics to predict equipment failures before they happen.

Integrated CMMS – Integrated CMMS connects with other enterprise systems, such as ERP, procurement, or financial management software, to provide a holistic view of operations.

Standalone CMMS – A standalone CMMS is a simple system that focuses specifically on maintenance management without integration with other enterprise systems.

Automated Maintenance CMMS – Automated CMMS systems use automation tools to schedule, track, and execute maintenance tasks without manual intervention.

Summary of CMMS Types:

| Type | Best For | Key Features |

|---|---|---|

| Cloud-Based CMMS | Businesses needing flexibility and remote access | Scalable, accessible from anywhere, automatic updates |

| On-Premise CMMS | Large enterprises or those with high security needs | Full data control, customizable, secure |

| Mobile CMMS | Field technicians and remote teams | Real-time updates, mobile access, efficiency |

| EAM (Enterprise Asset Management) | Large organizations with complex asset needs | Comprehensive asset lifecycle management |

| Work Order Management Systems (WOMS) | Organizations focused on work order tracking | Streamlined work order creation and management |

| Predictive Maintenance CMMS | Organizations with mission-critical assets | Early failure detection, condition-based monitoring |

| Integrated CMMS | Large companies requiring integration with other systems | Data integration across business functions |

| Standalone CMMS | Smaller organizations with basic needs | Simple, low-cost solution for maintenance tracking |

| Automated Maintenance CMMS | Companies looking to automate tasks | Task automation, reduced manual intervention |

How can a Computerized Maintenance Management System software help an organization?

A CMMS helps an organization by improving maintenance efficiency, reducing downtime, and extending the lifespan of assets. It streamlines work orders, schedules preventive maintenance, tracks inventory, and provides data-driven insights to optimize performance and cut costs.

What does a Computerized Maintenance Management System software do?

A Computerized Maintenance Management System (CMMS) is software designed to help organizations streamline and optimize their maintenance operations.

Here’s what a CMMS typically does:

- Work Order Management: It creates, tracks, and manages work orders for routine or emergency maintenance tasks. Maintenance staff can access these orders to understand what’s needed, when it’s needed, and track completion.

- Asset Management: It keeps an organized database of all equipment, machinery, and assets, recording details like age, location, maintenance history, and warranty information.

- Preventive Maintenance Scheduling: CMMS can schedule and automate preventive maintenance tasks based on time intervals, usage, or condition, helping to reduce downtime and extend the lifespan of assets.

- Inventory Management: It tracks spare parts and inventory levels, ensuring necessary materials are always available when needed for repairs or maintenance.

- Reporting and Analytics: It generates reports and analytics on maintenance activities, costs, performance, and equipment health, allowing managers to make informed decisions on resource allocation, budgeting, and future planning.

- Compliance and Safety: CMMS helps organizations stay compliant with regulations by keeping detailed records of maintenance activities and ensuring safety standards are met.

Cost Savings with CMMS

A Computerized Maintenance Management System (CMMS) can bring significant cost savings to an organization by improving efficiency, reducing downtime, extending asset life, and optimizing maintenance practices.

Reduction in Downtime

Preventive Maintenance (PM): By automating and scheduling regular preventive maintenance, CMMS helps prevent unexpected breakdowns. Routine checks and minor repairs reduce the chances of major failures, which can be costly due to lost productivity and emergency repair costs.

Fewer Reactive Repairs: CMMS minimizes reactive (emergency) maintenance, which is typically much more expensive due to the need for urgent repairs, overtime, and potentially higher parts costs.

Extended Equipment and Asset Life

Prolonging Asset Lifespan: Regular, well-documented maintenance extends the life of assets and machinery by preventing wear and tear. A CMMS can track maintenance history and performance, ensuring that assets are serviced at the right intervals, reducing the likelihood of premature failure.

Optimized Replacement Schedule: By analyzing asset data, CMMS can help determine the best time to replace aging assets or upgrade them before they become liabilities.

Inventory Optimization

Smarter Inventory Management: CMMS helps track spare parts and inventory levels in real-time. By reducing overstocking and minimizing stockouts, organizations can avoid unnecessary inventory holding costs and prevent delays caused by not having the right parts on hand.

Reduced Emergency Purchases: With better visibility into inventory needs, CMMS helps prevent last-minute, expensive emergency purchases or shipping fees for urgently needed parts.

Improved Labor Efficiency

Streamlined Work Orders: CMMS automates work order creation and scheduling, making it easier to assign tasks, prioritize work, and track labor hours. This ensures that maintenance personnel are utilized effectively, minimizing idle time and increasing productivity.

Reduced Overtime Costs: By ensuring that maintenance is performed on time and as scheduled, CMMS reduces the need for overtime to fix unexpected breakdowns, which can be costly.

Better Budget Control

Cost Tracking and Reporting: CMMS software provides detailed reports on maintenance costs, labor hours, parts, and materials, making it easier to identify areas where savings can be made.

Data-Driven Decision-Making: With better access to historical data and maintenance trends, managers can make more informed decisions on resource allocation, project priorities, and long-term maintenance strategies, potentially lowering costs in the process.

Energy Efficiency

Optimized Equipment Use: A CMMS can track the performance of machines and facilities, helping to identify inefficient equipment. Preventive maintenance and timely repairs ensure machines run at peak performance, reducing energy consumption and utility costs.

Preventing Overuse: By ensuring that assets are regularly maintained, CMMS can help prevent machinery from running longer than necessary, saving on energy costs.

Regulatory Compliance and Avoiding Fines

Avoid Compliance Penalties: Many industries are required to comply with safety regulations and maintenance standards. A CMMS can help ensure that inspections and maintenance tasks are completed on schedule, reducing the risk of non-compliance fines or penalties.

Safety and Risk Reduction: Keeping equipment in safe, working condition also reduces the likelihood of accidents, which can be expensive due to worker compensation claims, insurance costs, and potential legal fees.

Improved Decision-Making and Strategic Planning

Predictive Maintenance: By analyzing historical data, a CMMS can help predict when equipment is likely to fail, allowing you to schedule maintenance proactively.

Data-Driven Optimization: With clear insights into asset performance and maintenance trends, organizations can make data-driven decisions to optimize workflows, adjust maintenance schedules, and reduce unnecessary spending.

Reduced Vendor Costs

Outsourcing Control: With accurate records of your assets’ condition and maintenance history, you’re in a better position to negotiate with third-party service providers or contractors.

Informed Purchasing: Knowing the condition and history of equipment can help you avoid buying unnecessary parts or services.

Improved Operational Efficiency

Reduced Paperwork: With CMMS, you no longer need to rely on manual tracking of maintenance requests, work orders, or asset data, reducing administrative overhead and associated costs.

Automated Task Management: Automation features in CMMS free up time for your team to focus on more valuable tasks rather than spending time on manual scheduling, tracking, or paper-based record-keeping.

By increasing operational efficiency, extending asset life, preventing unplanned downtime, and optimizing resources, a CMMS can result in substantial cost savings for an organization.

FAQ about Advertising Agency Software

What is a CMMS?

A Computerized Maintenance Management System (CMMS) is software that helps organizations manage, track, and streamline maintenance tasks, work orders, and asset management. It helps improve operational efficiency, extend asset life, reduce downtime, and optimize maintenance processes by automating and centralizing maintenance data.

How does a CMMS improve preventive maintenance?

CMMS automates the scheduling of preventive maintenance tasks based on time intervals, usage, or condition, ensuring that maintenance is done before failures occur. The system sends reminders and alerts when a task is due, reducing the likelihood of unexpected breakdowns and helping to maintain equipment at optimal performance.

Can CMMS be used for managing inventory?

Yes, CMMS includes inventory management features that allow you to track spare parts, materials, and supplies. It helps optimize stock levels, avoid overstocking or stockouts, and ensures that the right parts are available when needed for repairs or maintenance tasks.

How does CMMS help with asset management?

CMMS allows you to store and manage detailed records for each asset, including specifications, maintenance history, warranty information, and location. This centralized database helps track the performance, condition, and lifecycle of assets, making it easier to plan maintenance, predict replacements, and optimize asset usage.

Is CMMS only for large organizations, or can small businesses use it too?

CMMS is scalable and can be beneficial for both small and large organizations. Small businesses can use a CMMS to improve maintenance efficiency, even with fewer assets and employees. Many CMMS solutions offer flexible pricing and features that are suitable for businesses of various sizes.

Can CMMS software be used on mobile devices?

Yes, many CMMS systems offer mobile applications or responsive web interfaces that allow maintenance technicians and managers to access work orders, check asset data, update maintenance statuses, and track inventory from their smartphones or tablets while on the go.

How secure is the data in a CMMS?

Data security in CMMS software is critical. Most modern systems employ encryption, secure cloud storage, and role-based access controls to protect sensitive maintenance and asset data. Many cloud-based CMMS systems also offer regular backups to ensure data is safe and recoverable.

Does CMMS help with compliance and safety regulations?

Yes, CMMS helps ensure compliance with industry-specific regulations by tracking maintenance activities, inspections, safety audits, and certifications. It maintains records of compliance efforts and generates reports to prove that maintenance tasks are performed according to required standards.

Can CMMS be used to track equipment performance or failures?

Yes, CMMS can track equipment performance through historical data, maintenance logs, and condition-based monitoring. It can help identify patterns or trends related to asset failures, allowing you to take preventive measures before equipment fails unexpectedly.

How long does it take to implement a CMMS?

The time required for CMMS implementation depends on the complexity of your organization and the system itself. It can take anywhere from a few weeks to a few months. Factors that influence implementation time include the number of assets and users, the need for customization, data migration from old systems, and employee training.

Can a CMMS integrate with other systems?

Yes, many CMMS solutions offer integration with other enterprise systems, such as ERP (Enterprise Resource Planning), accounting software, or IoT devices.

What are the costs associated with a CMMS?

The cost of CMMS software can vary widely depending on factors like the number of users, features, deployment type (cloud-based or on-premise), and whether it’s a subscription model or a one-time purchase. Many vendors offer subscription-based pricing, ranging from a few dollars per user per month to hundreds of dollars per month for enterprise-level solutions. Additional costs may include training, support, and integrations.

Key takeaways

CMMS software is a powerful tool for improving the efficiency, reliability, and cost-effectiveness of maintenance operations. By automating workflows, extending asset life, reducing unplanned downtime, and providing valuable insights, CMMS can lead to significant cost savings and help your organization operate more smoothly and efficiently.

Personal contact info – slikgepotenuz@gmail.com

Permanent Address :- Montville, NJ

CEO and co-founder at Cloudsmallbusinessservice.com