Supply chain software is a tool or platform designed to help businesses manage and optimize their supply chain activities. It enables companies to plan, monitor, and coordinate the various stages involved in production, from raw materials sourcing to final delivery to customers. These software solutions typically automate and streamline supply chain processes, providing better visibility, control, and decision-making across the entire supply chain.

Discover the top 10 supply chain software solutions and analytics platforms

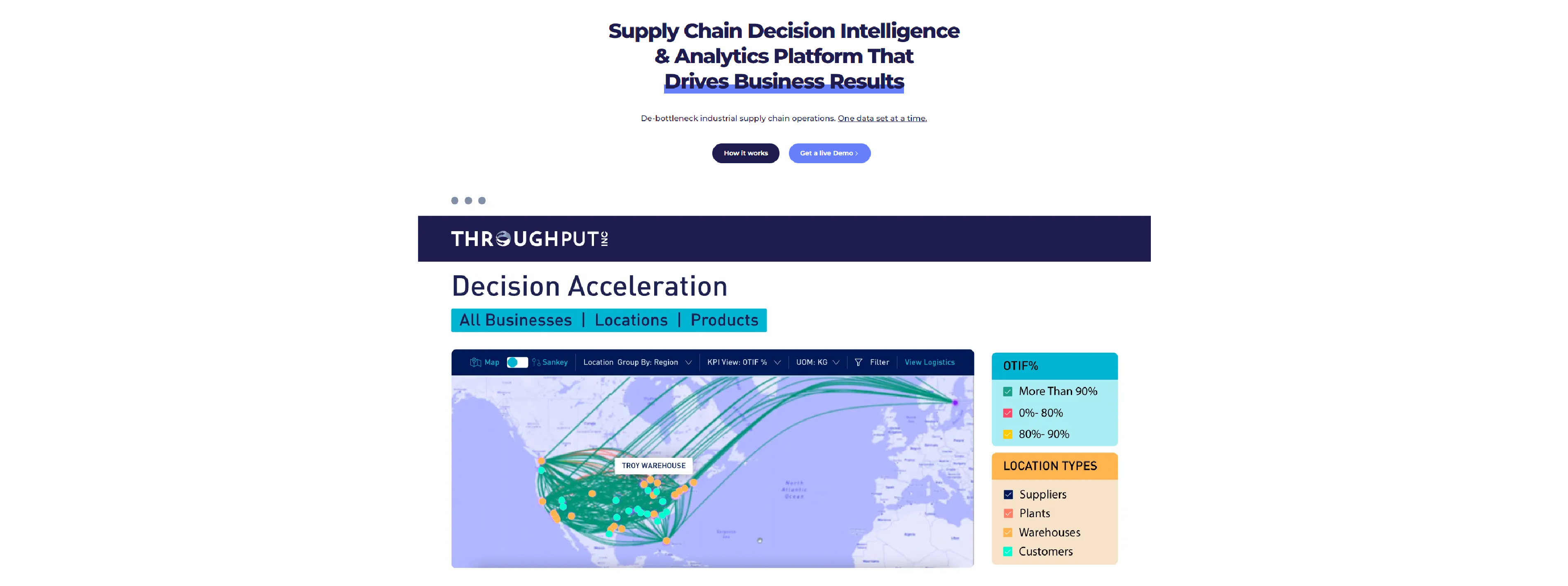

Throughput

Throughput – AI-powered supply chain intelligence and analytics platform that improves demand sensing, and capacity planning and unlocks supply chain profitability.

- Leverage ThroughPut to stay on top of your supply chain transformation’s financial outcomes

- Holistically improve top as well as bottom line growth with real-time, actionable insights

- Identify performance deviations in real time. Get to the root of supply chain inefficiencies

- Eliminate redundant processes

O9solutions

o9 supply chain analytics software and align supply chain policies with business strategies and market needs.

- Capture full impact across the entire network, such as inventory influencers for downstream recommendations with the :o9 Enterprise Knowledge Graph

- Efficient frontier and sensitivity analysis on multiple simultaneous scenarios. Demand Prioritization and supply allocation can contribute to the in-depth “what-if” scenarios

- Capture cost savings and eliminate value leakage in the material planning and procurement systems

Sas

With supply chain analytics from SAS, retail and consumer goods companies can achieve profitability while meeting omnichannel customer demand, without over- or under-stocking.

- Seamlessly bring together market and consumer drivers, such as syndicated scanner data and social media sentiment, with machine learning models to connect shopper engagement to product demand

- Get near-real-time insight into supply and demand dynamics

- Use time-series and machine learning forecasting that considers intermittent demand, new product launches and dropped items. Let the solution choose the best algorithms or build your own with SAS or open source models

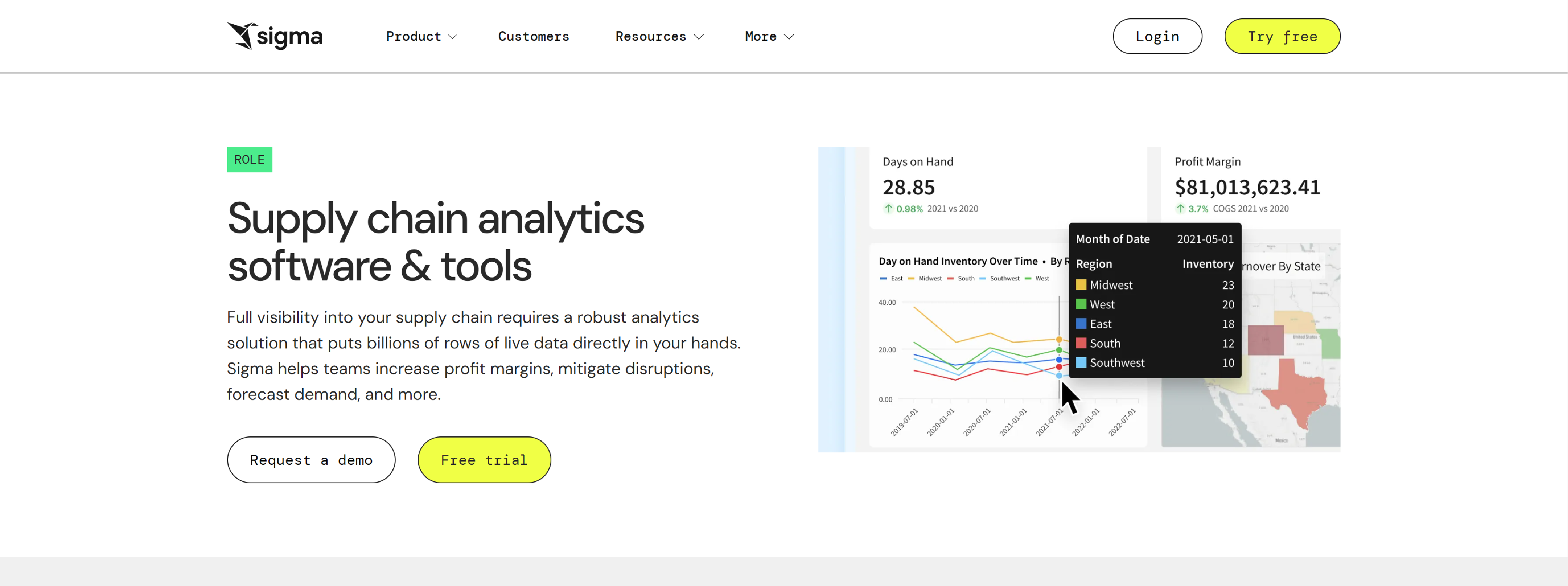

Sigmacomputing

Sigmacomputing – Full visibility into your supply chain requires a robust analytics solution that puts billions of rows of live data directly in your hands.

- Effortless, direct connections

- Trusted security and compliance

- Intelligent querying for enhanced efficiency

- Precision control, uncompromising security

Scnsoft

ScienceSoft help businesses design, implement and modernize supply chain analytics solutions to consolidate supply chain data under one roof, achieve visibility into supply chain operations, and support the decision-making for supply chain planning and optimization.

- Analysis of supply chain analytics needs and drawing up requirements for supply chain analytics software

- Supply chain analytics solution conceptualization and tech selection

- Supply chain analytics solution development

- Supply chain analytics software quality assurance

- After-launch support and optimization

Alteryx

Alteryx streamlines analytics, empowering analysts to lead decision-making improvements across the supply chain.

- Gain deeper insights into every facet of your supply chain to identify efficiencies and respond faster to market changes

- Minimize risk by leveraging predictive analytics to foresee potential disruptions or warning signs and adapt proactively

- Improve responsiveness, reduce costs by automating repetitive tasks, all while giving decision makers self-service access to the latest prescriptive insights

Luzmo

Luzmo – Add an embedded analytics dashboard to your logistics, supply chain or mobility software app.

- Add a data analytics feature and empower better decision-making in your users

- Delight your customers with an intuitive and interactive analytics solution, inside your logistics app

- Drive revenue expansion with embedded dashboard as an add-on feature

Freightpop

FreightPOP logistics and supply chain analytics help you understand your supply chain expenses and make smarter decisions in the future.

- Carrier lane data (multi-mode)

- Spend by carrier and mode

- Quote/invoice discrepancies

- Shipping rate compliance

- And more!

Qrvey

Qrvey – Optimize your supply chain to maximize efficiency and cut costs with a modern analytics platform that was built for today big data needs.

- Improve process planning and forecasting using supply chain analytics solutions

- Use IoT sensors to monitor manufacturing logistics equipment and parameters and adapt efficiently

- Reduce fuel consumption and improve driving efficiency using analytics and GPS technologies

- Analyze patterns within SaaS applications and enable customers to use custom data models

- Make the most efficient use of warehouse space and minimize travel distances

- Use RFID for shelf-space optimization, dynamic pricing and out-of-stock prevention

Latentview

LatentView, one of the top supply chain analytics companies, provides advanced solutions to streamline operations, improve transparency, and reduce costs.

- Predict customer demand with a high degree of accuracy, including internal and external signals, using our demand forecasting solutions

- Ensure “balance” in the constantly oscillating supply chain network to have the right amount of inventory to meet customer demand without incurring excessive inventory-carrying costs

- Move beyond heuristics and gut feel to enable intelligent decisions around Inventory placement, allocation, replenishment, and the cascading upstream impact on production schedules and procurement cadences

What is Supply Chain Analytics Software?

Supply Chain Analytics Software is a specialized type of software designed to help businesses analyze and optimize their supply chain operations. It leverages data analytics, machine learning, and artificial intelligence to provide insights into the performance of various supply chain functions, enabling companies to make data-driven decisions that enhance efficiency, reduce costs, and improve overall supply chain performance.

What are the Key Features and Functionalities of Modern Supply Chain Analytics Tools?

Modern supply chain analytics tools offer a range of key features and functionalities designed to optimize operations and improve decision-making

- Real-Time Data Analysis: Provides real-time visibility into supply chain operations, enabling quick responses to disruptions, delays, or opportunities.

- Demand Forecasting and Planning: Uses historical data, market trends, and predictive analytics to forecast future demand accurately.

- Inventory Optimization: Analyzes inventory levels across the supply chain to ensure optimal stock, reducing carrying costs and improving cash flow.

- Supplier and Vendor Performance Management: Tracks key performance indicators (KPIs) such as lead time, quality, delivery performance, and cost for each supplier.

- Logistics and Transportation Optimization: Optimizes shipping routes, transportation modes, and delivery schedules to minimize costs and improve delivery times.

- Scenario Planning and Simulation: Allows businesses to model and simulate different scenarios (e.g., demand fluctuations, supplier disruptions) to understand potential outcomes.

- Cost Analysis and Optimization: Analyzes costs across the supply chain, identifying areas where savings can be achieved, such as transportation, procurement, and warehousing.

- Risk Management and Mitigation: Identifies risks such as supply disruptions, natural disasters, or geopolitical issues by analyzing patterns and external factors.

- End-to-End Supply Chain Visibility: Offers a holistic view of the entire supply chain, from raw materials to finished product delivery, allowing for better monitoring and control.

- Advanced Analytics and Reporting: Uses machine learning, AI, and big data analytics to uncover hidden patterns and trends within the supply chain.

- Collaboration and Communication Tools: Facilitates collaboration between departments, suppliers, and customers through integrated platforms, enhancing communication and coordination.

- Sustainability and Environmental Impact Tracking: Monitors the environmental impact of supply chain operations, such as carbon emissions, energy use, and waste.

What are the Benefits of Using Supply Chain Analytics Tools for Businesses?

Using supply chain analytics tools offers a range of benefits for businesses, helping them streamline operations, improve efficiency, and achieve better outcomes across the entire supply chain.

- Improved Decision-Making: By providing real-time data and actionable insights, supply chain analytics tools enable businesses to make data-driven decisions quickly and accurately.

- Cost Reduction: Analytics tools help identify inefficiencies, optimize processes, and reduce unnecessary expenses, such as overstocking, transportation costs, and supplier-related expenses.

- Enhanced Forecasting and Demand Planning: These tools analyze historical data, market trends, and other factors to generate more accurate demand forecasts.

- Increased Supply Chain Visibility: Supply chain analytics tools provide real-time tracking and visibility across the entire supply chain, from suppliers to final delivery.

- Risk Mitigation: These tools identify potential risks, such as disruptions, delays, or supplier failures, and provide insights into how to mitigate them.

- Better Supplier and Vendor Management: Supply chain analytics tools track supplier performance based on criteria like lead time, quality, and cost.

- Optimized Inventory Management: These tools help businesses maintain the right balance of inventory, avoiding stockouts while minimizing overstock and storage costs.

- Increased Efficiency and Productivity: By automating tasks like demand forecasting, order management, and inventory tracking, businesses can streamline operations and reduce manual intervention.

- Improved Customer Satisfaction: Accurate demand forecasting, efficient inventory management, and optimized logistics lead to better product availability and timely deliveries.

- Scalability and Flexibility: Supply chain analytics tools are scalable and can adapt to the growing needs of businesses as they expand or enter new markets.

- Sustainability and Environmental Impact: Many analytics tools include features that monitor environmental impact, such as carbon emissions and waste, helping businesses track and reduce their ecological footprint.

- Competitive Advantage: By using advanced analytics to optimize supply chain processes, businesses can respond faster to market changes, reduce costs, and improve customer experiences.

What are Data Visualization Techniques for Effective Decision-making in Supply Chain?

Data visualization techniques are essential in supply chain analytics because they help businesses turn complex data into clear, actionable insights. By presenting data visually, decision-makers can quickly identify trends, patterns, and anomalies that would be difficult to spot in raw data.

- Dashboards: Dashboards help monitor the overall health of the supply chain in real-time, allowing decision-makers to quickly detect issues and take immediate action.

- Bar and Column Charts: Charts are effective for identifying performance trends, comparing different suppliers, or analyzing sales across product categories or geographic regions.

- Heatmaps: Heatmaps can visualize areas such as inventory levels across warehouses or order fulfillment times across regions.

- Pie Charts: Pie charts can be used to show the distribution of total supply chain costs, such as the proportion of expenses spent on transportation, warehousing, or procurement.

- Line Graphs: Line graphs are commonly used to track changes in demand, inventory levels, or order lead times over specific periods.

- Flow Charts: Flow Charts useful for mapping out workflows in the supply chain, such as order processing, supplier interactions, or inventory management.

- Gantt Charts: In supply chain management, Gantt charts are helpful for tracking project progress, such as the launch of new products, vendor contracts, or seasonal promotions.

- Geospatial Maps (Heatmaps and Geomaps): Geospatial Maps help visualize logistics routes, identify optimal shipping lanes, and pinpoint areas with high shipping costs or delays.

- Sankey Diagrams: Sankey diagrams are useful for visualizing the movement of goods from suppliers to customers, tracking cost breakdowns across different supply chain stages, or analyzing material waste and energy consumption in the supply chain.

- Scatter Plots: Scatter plots help visualize correlations, such as between supplier performance and delivery times, or between inventory turnover and sales volume.

- Treemaps: Treemaps are useful for visualizing complex, hierarchical data such as inventory levels across product categories or the cost breakdown by supply chain functions.

- Box Plots: Box plots can visualize the variation in lead times, supplier delivery times, or demand variability.

- KPI Indicators and Speedometers: KPI visualizations are useful for tracking performance against supply chain goals such as on-time delivery, order accuracy, or inventory turnover rates.

- Network Graphs: Network Graphs help visualize supply chain networks, identify potential bottlenecks, and assess the efficiency of supply chain connections.

How to Run Expense Management and Cost Optimization Using Supply Chain Analytics Software?

Running expense management and cost optimization with supply chain analytics software involves using data-driven insights to streamline operations, reduce inefficiencies, and improve decision-making throughout the supply chain. The software helps businesses identify where costs are accumulating, track performance metrics, and forecast future trends, all of which are essential for managing expenses effectively.

First, by analyzing data on procurement, transportation, inventory, and production, the software enables businesses to identify key cost drivers. These insights allow companies to pinpoint areas where they can reduce costs, such as renegotiating supplier contracts, optimizing inventory levels, or improving transportation routes. For example, if shipping costs are high due to inefficient routes or excess inventory is being stored at costly warehouses, the software will highlight these areas for improvement.

Next, the software helps businesses optimize inventory management. By using predictive analytics, it forecasts demand more accurately, ensuring that inventory levels are aligned with actual needs. This reduces the risk of overstocking or stockouts, both of which can lead to unnecessary costs. Accurate forecasting also improves cash flow, as companies don’t have excess capital tied up in unsold goods.

Cost-to-serve analysis is another key feature. The software allows businesses to evaluate the total cost of serving specific customers or markets, helping them understand which segments are more expensive to serve. This insight can lead to pricing adjustments or better targeting of resources, ensuring that high-cost customers or regions are managed more efficiently.

The software facilitates real-time monitoring of key performance indicators (KPIs), such as order fulfillment accuracy, lead times, and supplier performance. By tracking these metrics, companies can quickly spot inefficiencies and take corrective actions, further reducing costs across the supply chain.

Key performance indicators (KPIs) for measuring supply chain success

Key performance indicators (KPIs) for measuring supply chain success help businesses track efficiency, cost management, and customer satisfaction. Crucial KPIs include on-time delivery, which measures the percentage of orders delivered as promised, and order accuracy, ensuring products are delivered correctly. Inventory turnover assesses how efficiently inventory is sold and replenished, while lead time tracks the time from order receipt to delivery. Other important KPIs like perfect order rate, freight cost per unit, and supplier performance measure how well the supply chain meets customer expectations, controls costs, and maintains supplier reliability. Monitoring these KPIs helps optimize supply chain operations and drive continuous improvement.

General FAQ for Supply Chain Analytics Software

Q: What is Supply Chain Analytics Software?

A: Supply Chain Analytics Software is a tool that helps businesses collect, analyze, and interpret data across their supply chain operations. It leverages technologies like big data, machine learning, and predictive analytics to provide insights into areas such as inventory management, demand forecasting, procurement, transportation, and supplier performance.

Q: How does Supply Chain Analytics Software benefit businesses?

A: Supply Chain Analytics Software helps businesses by offering data-driven insights that improve decision-making, enhance operational efficiency, and reduce costs. By tracking and analyzing key metrics, businesses can identify inefficiencies, optimize inventory levels, forecast demand more accurately, and streamline logistics.

Q: What features should a good Supply Chain Analytics Software include?

A: A good Supply Chain Analytics Software should include features such as real-time data visualization, predictive analytics, demand forecasting, inventory management, supplier performance tracking, and scenario analysis.

Q: How does Supply Chain Analytics Software improve forecasting accuracy?

A: Supply Chain Analytics Software improves forecasting accuracy by analyzing historical data, market trends, and other relevant factors to predict future demand. By using advanced algorithms and machine learning models, the software can anticipate shifts in demand more accurately than traditional methods, helping businesses adjust production schedules and inventory levels accordingly.

Q: What role does data visualization play in Supply Chain Analytics Software?

A: Data visualization is a crucial component of Supply Chain Analytics Software because it converts complex data into easy-to-understand charts, graphs, and dashboards.

Q: Can Supply Chain Analytics Software help reduce costs?

A: Yes, Supply Chain Analytics Software can help reduce costs by identifying inefficiencies, optimizing inventory management, and streamlining logistics. By providing insights into areas like transportation costs, procurement expenses, and supplier performance, businesses can make data-driven decisions that minimize waste, improve procurement strategies, and reduce unnecessary expenses.

Q: How does Supply Chain Analytics Software assist in risk management?

A: Supply Chain Analytics Software assists in risk management by identifying potential risks, such as supply chain disruptions, delays, or supplier failures, and providing insights on how to mitigate them. It uses data to monitor factors like supplier performance, geopolitical risks, and market fluctuations, allowing businesses to anticipate and address issues before they impact operations.

Q: Is Supply Chain Analytics Software scalable?

A: Yes, most Supply Chain Analytics Software solutions are scalable, meaning they can grow with a business as its operations expand.

Q: How can Supply Chain Analytics Software contribute to sustainability?

A: Supply Chain Analytics Software can contribute to sustainability by providing insights into areas such as carbon emissions, waste reduction, and resource utilization. It can track and analyze the environmental impact of transportation, manufacturing, and sourcing decisions, helping businesses make more sustainable choices.

Q: How does Supply Chain Analytics Software support decision-making?

A: Supply Chain Analytics Software supports decision-making by providing real-time data and actionable insights that help leaders make informed, data-driven choices. It helps evaluate different scenarios, track performance metrics, and visualize key trends. By making this information easily accessible and understandable, the software enables businesses to respond quickly to changing market conditions, optimize processes, and improve overall supply chain effectiveness.

Supply Chain Analytics Software plays a pivotal role in transforming data into actionable insights, enabling businesses to optimize their entire supply chain. By leveraging advanced analytics, businesses can make data-driven decisions that enhance efficiency, reduce costs, improve forecasting, and boost overall performance.